Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: DZ-1526 01

Brand: DIZO

Voltage:: 220v

Packing SizeW*H*D(CM):: 80*55*120

Application:: PP PA non-woven fabric PSA Card, Grading Card, Sports Card, Card Slab .Plastic Card Seal Welding,Pokemon card Welding

Delay Time:: 0.01-99.99s

Max Output Power:: Φ180

NW(KG):: 120kg

Model:: 15k 2600

Power:: 2600w

Frequency:: 15KHZ

Packaging: export wooden box

Productivity: 1000unit

Transportation: Ocean,Air,Express

Place of Origin: wuxi

HS Code: 8515809090

Port: Shanghai,Noingbo,Shenzhen

Payment Type: T/T,L/C,D/P,D/A,Paypal

Incoterm: DDP,FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDU,Express Delivery,DAF,DES

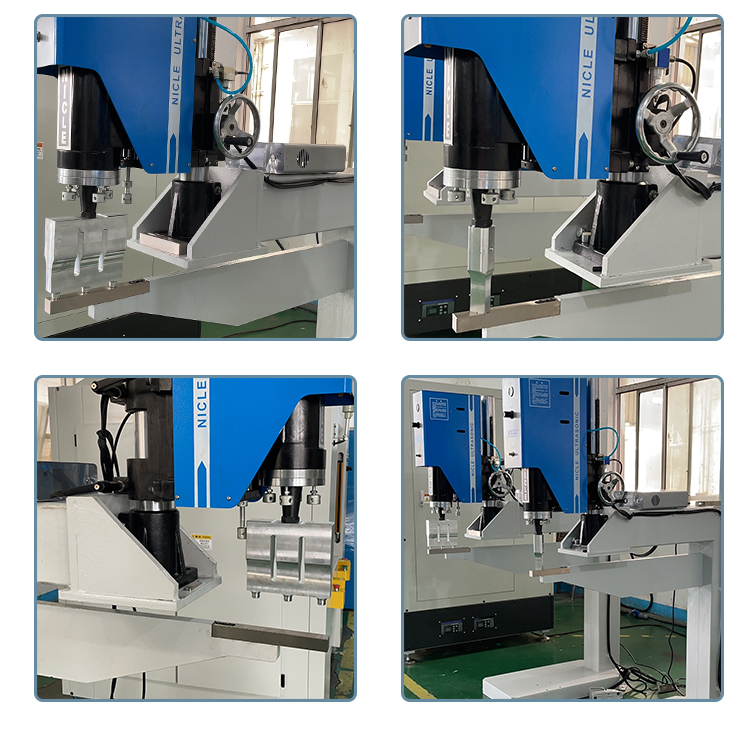

With the concept of green environmental protection, the concept of recycling and reuse was born in the field of packaging, and the development of new materials has become an industry trend. The large number of development and application of polypropylene hollow board has made the trend of recycling more and more obvious. Polypropylene (PP) honeycomb board is a plate made of two thinner panels firmly composite on both sides of the thicker honeycomb core, also known as honeycomb sandwich structure, and the material is mainly PP. This kind of plastic hollow board has the characteristics of light weight and high rigidity, moisture proof and waterproof, green environmental protection, and excellent energy absorption. PP honeycomb panels are used in many fields with their unique advantages, especially automotive containers, containers and packaging express boxes. 15k2600w Plastic Ultrasonic Welding Machine can weld plastic hollow plates In production, the welding of PP hollow plates adopts the Plastic Ultrasonic Welding Machine, and the principle is to heat and melt the plastic molecules at the two welding surfaces, so as to consolidate together. Ultrasonic Welding Machine is widely used in the welding of thermoplastic materials because of its high weld strength, good weld quality, and automatic molding. Among them, temperature, time and pressure are the main factors affecting welding strength and welding appearance.

PP PA Ultrasonic Welding Machine pressure is the most significant among the four factors, the analysis of the reasons includes two aspects: one is the hollow plate is a material with a certain thickness and pore structure, in the process of ultrasonic welding, a large number of pores will lose the ultrasonic energy generated from the welding head, so that the temperature generated by the energy reaching the welding surface cannot reach the melting point of polypropylene, so the pressure is needed to reduce the distance and porosity between the honeycomb plates; Secondly, during the melting process of the material, the pressure can promote the mutual movement of the molecules, so that the two welding surfaces are closely combined, and as the welding surface cools and the material solidifies, the molecular internal force generated at the weld seam is generated to improve the welding strength. In general, for semi-crystalline materials with low hardness such as PP, the ultrasonic energy decays quickly, so it is only suitable for near-field welding.

| Model | DZ-2018TA Ultrasonic welding machine |

| Price | $3000 |

| Frequency | 15KHZ |

| Power | 2600W |

| Application | scouring pad ,dishcloth,wash king |

| Delay Time/Weld time/Hold Time | 0.01-9.99s |

| Voltage | 110V/220V |

| Max output power | 2600kw |

| Welding Area | Φ180 |

| packing sizeW*H*D(CM) | Machine Frame:400*650*1100Generater:210*320*80 |

| Advantage | Accurate temperature control/Flexible Manufacturing/Low Maintenance Cost/Sustainable/Low Noise Level/High Safety Level/Easy to Operate/Long Service Life/High Rigidity/High-accuracy |

| NW(KG) | 120KG |

Product Categories : Ultrasonic Welding Machine > Plastic Ultrasonic Welding Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.