Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: DZ-1542TA

Brand: dizo

Model: DZ-1542TA Ultrasonic welding machine

Price: $3000-$3900

Frequency: 15KHZ

Power: 4200W

Application: PP/PA/PVC material

Delay Time/Weld Time/Hold Time: 0.01-9.99s

Voltage: 110V/220V

Max Output Power: 4.2kw

Welding Area: Φ300

Packing SizeW*H*D(CM): Machine Frame:400*650*1100Generater:210*320*80

Productivity: 1000/year

Transportation: Express,Air,Land,Ocean

Place of Origin: wuxi

HS Code: 8515809090

Port: SHANGHAI,NINGBO,SHENZHEN

Payment Type: L/C,T/T,D/A,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,DDU,CFR,Express Delivery,CIF,EXW,DAF,FAS,DES,FCA,CPT,CIP,DEQ,DDP

parameter

Model

DZ-1542TA Ultrasonic Welding Machine

Price

$3000-$3900

Frequency

15KHZ

Power

4200W

Application

PP/PA/PVC material Ultrasonic Fly Swatter Welder

Delay Time/Weld time/Hold Time

0.01-9.99s

Voltage

110V/220V

Max output power

420kw

Welding Area

Φ300

packing sizeW*H*D(CM)

Machine Frame:400*650*1100Generater:210*320*80

Advantage

Accurate temperature control/Flexible Manufacturing/Low Maintenance Cost/Sustainable/Low Noise Level/High Safety Level/Easy to Operate/Long Service Life/High Rigidity/High-accuracy

NW(KG)

140KG

The 15k 4200w Plastic Ultrasonic Welding Machine welding process is easy to operate, safe and reliable, and the welding speed is fast, which reduces the cost of the product and improves the economic benefit. At the same time, riveting, embedding, cutting, forming, sealing, etc. can also be used for welding, and the welding forms are diverse, which can meet the requirements of different occasions. The outstanding advantages of Ultrasonic Welding Machine just overcome the fatal shortcomings of traditional plastic adhesion, and can realize large-scale mass production of products and automatic control. With the extensive use of ultrasonic welding, more and more people need to understand the principle of ultrasonic fly swatter welder.

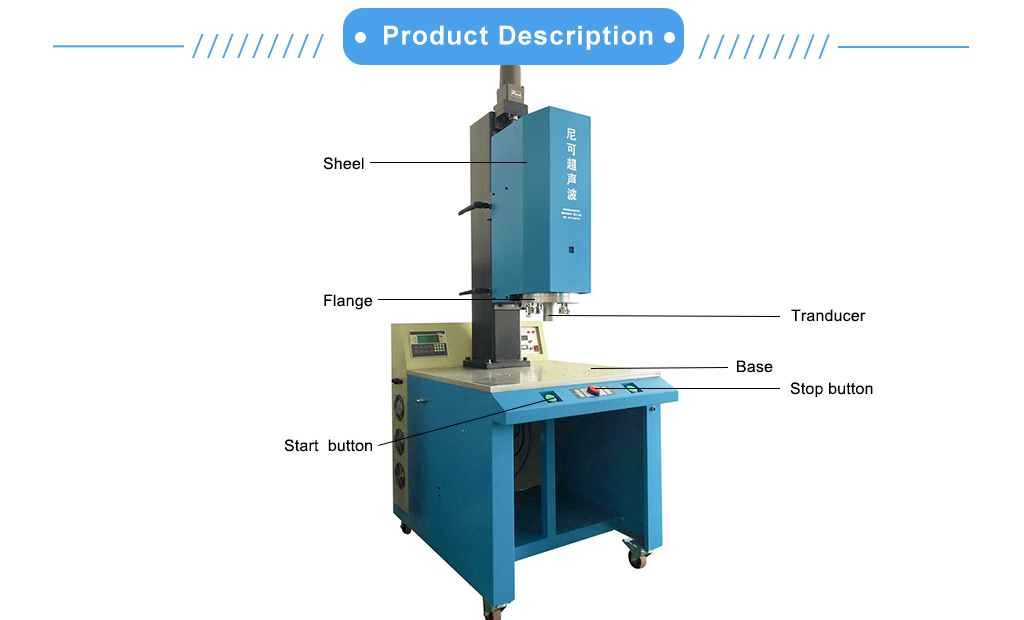

Analog Ultrasonic Plastic Welder is mainly composed of main circuit, acoustic system, pneumatic pressure system, automatic control system, and mechanical parts. The acoustic system is the most important part. The acoustic system consists of a transducer, an amplitude modulator, and a welding horn.

The inverter converts the power frequency alternating current into high frequency alternating current and provides it to the transducer. The transducer converts high-frequency AC electrical energy into high-frequency vibration energy. The function of the amplitude modulator is to adjust the amplitude of vibration. The welding head transmits high-frequency vibration energy to the welding surface between the welding parts, so that the welding surface vibrates at high frequency. The basic principle of ultrasonic plastic welding is to apply a certain static pressure to the plastic parts that are joined by two welding surfaces. While maintaining a certain static pressure, high-frequency vibration energy is transferred to the welding surface. Under the action of this vibration, an instant high temperature is generated on the welding surface to form a molten layer between the welding surfaces, and then the vibration is stopped and the static pressure is maintained for a period of time to melt the layer. Solidification, so as to achieve a firm bond of the welding surface. Because the vibration frequency during welding is higher than 20KHz, this frequency is higher than the hearing range of the human ear, so it is called ultrasonic welding.

The principle of ultrasonic welding can be summarized as that, ultrasonic welding first transfers energy to the welding surface through high-frequency vibration to cause the temperature to rise, then the plastic melts, and then the plastic solidifies through a holding pressure time to complete the welding. So I said that the ultrasonic welding machine is not pressure welding, because the whole welding can not be completed without pressure, and the whole welding process cannot be completed with pressure alone.

Product Categories : Ultrasonic Welding Machine > 15k Ultrasonic Welding Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.